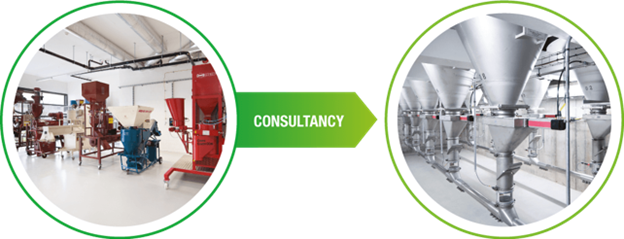

With such a broad seed treatment equipment market, customers understandably face a challenge selecting the right application technology and equipment. Yet successful seed treatment depends strongly on getting this right. That is where Syngenta Seedcare can help.

Consultancy

We make totally independent recommendations. The Seedcare Institute experts will help you assess state-of-the-art application technology for complex treatment solutions through a wide range of criteria. These can include direct and undiluted product injection versus mixture preparation in a slurry tank; the pros and cons for continuous versus batch treatment technologies for the crop range to be treated; engineering solutions to minimize operator exposure; fit of equipment into the overall seed factory layout; user-friendliness of equipment operations; and many more

Engineering your success

This support goes beyond treatment installation. Our Syngenta Seedcare experts also advise on preparation of slurries, control mechanisms to monitor application quality, and the handling of waste material. Working with customers’ engineering teams, we help ensure the equipment is integrated into the overall plant configuration seamlessly.

Recipe Development

Our ability to protect the seed and the seedling is ten times greater today.

Technology is moving swiftly. A decade ago, only a few fungicides in single or dual component formulations had been applied to seeds in a special coating. Today, up to 10 different technologies can be loaded onto the seed in one application. No wonder seed treatment has become the most attractive vehicle for delivering crop protection technology onto the seed. Our Seedcare products protect the seed from the day it is planted, through the most sensitive growth stages when they are most vulnerable to attack by diseases, insect pests, nematodes and abiotic stress, to improve the establishment of healthy crops.

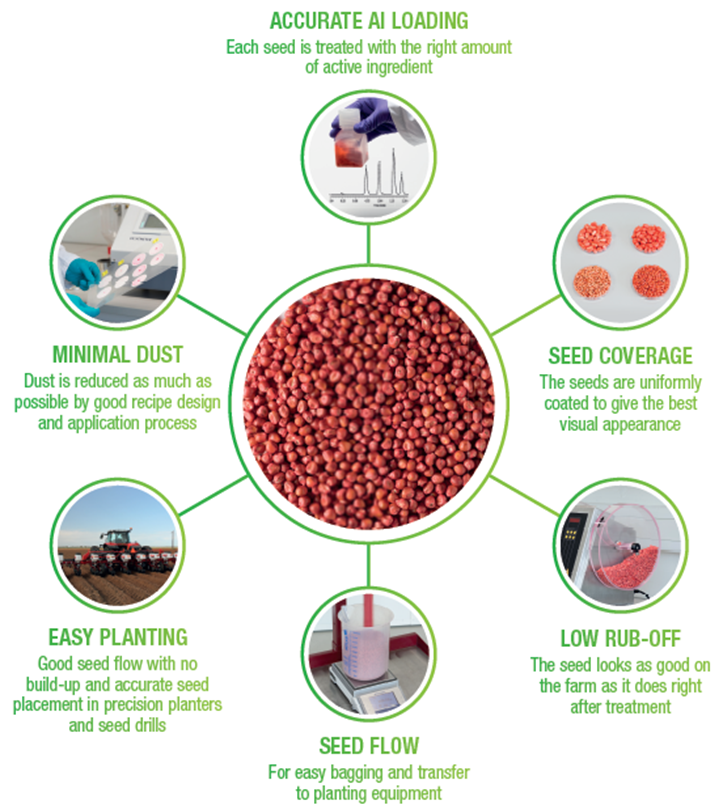

It all starts with a formulation that is then customized to meet local crop needs

A new formulation starts when the Seedcare Institute experts work with formulation chemists to select the best formulation candidate. In this process, the recipe for the target crop goes through many tests for specific quality criteria, ranging from dust-off to flowability, plantability, visual appearance, and cleaning performance of equipment.

Basic recipes are then customised. Variability between different crops and the same crop in different areas, as well as the need for different product combinations, make customization essential. Our local Seedcare Institute experts talk to customers in depth. This important dialog helps us understand customer needs on every single field so we can customise the formula to meet those needs.