Syngenta Seedcare Roadshow

The do’s and don’ts of seed quality testing

All tests are not created equal when it comes to measuring the impact of chemical treatments on seed. Initial quality and substrate choice are the devils in the detail.

Pannar, one of the largest field crop seed producers and suppliers in Africa, recently decided to introduce Syngenta’s Cruiser® Maxx Sunflower. The latter is a seed treatment that combines insecticide and fungicide products to optimally protect sunflower seed and seedlings in the critically important first 4-6 weeks after planting.

Understanding just how seed quality and seed safety are to Pannar and its customers, Syngenta brought Dr Brigitte Hamman, its Global Technical Manager: Seed Biology, to South Africa to conduct a workshop on seed testing with Pannar’s laboratory team.

The workshop took place on Monday, 3 February, at Pannar’s facility near Kempton Park in Gauteng. Similar workshops took place at other seed houses - Monsanto, Pioneer, Klein Karoo and Starke Ayres.

Dr Hamman had two main messages to convey. Firstly she explained the rigorous scientific processes applied by Syngenta’s Global Seedcare Institute in Switzerland when it develops seed treatments. Secondly, she highlighted the risk of false negatives in seed quality tests and how they can be avoided.

“When we put our chemicals on the seed, they should not alter its quality at all,” says Dr Hamman. “Our aim at the Seedcare Institute is to address all quality concerns so that the discussions with growers can be about crop and yield benefits.” She adds that there is no chemical that can bring a dead seed back to life or make a poor quality seed better. Cruiser® Maxx Sunflower’s power lies in its ability to protect the seed and the seedling against attacks from insects and seed- and soil-borne fungi.

In her presentation, Dr Hamman highlighted the importance of only treating high-quality seed with chemicals, especially if the seed will be stored. Poor quality seed deteriorates quickly and often chemicals are unfairly blamed for this natural phenomenon.

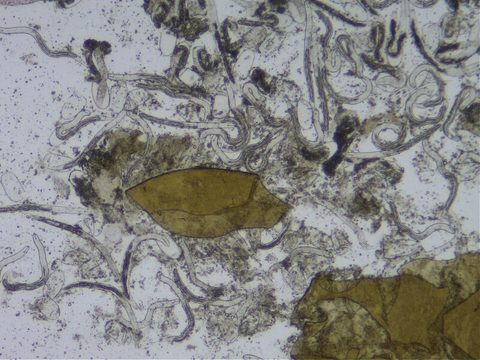

Syngenta and Pannar both use the rules of the International Seed Testing Organisation (ISTA) and the Association of Official Seed Analysts (AOSA) for seed testing. “The rules were set up based on untreated seed-lots and allow researchers to choose the substrate in which the seeds are planted,” explains Dr Hamman. “The choice ought not to influence results, but we have learnt that when evaluating treated seeds, substrate has a significant influence.” For example, when 100 treated seeds are placed in a petri dish to test standard germination, they end up in a chemical “soup” that is a far cry from normal planting conditions and does not measure the response of one seed to a single-seed load of chemicals. The recommended rolled towel technique provides a much more accurate testing environment.

“We are excited about Pannar’s decision to treat their sunflower seeds with Cruiser® Maxx Sunflower,” says Lukas Meyer (Key Account Manager: Seedcare, Syngenta South Africa). “With Brigitte’s visit we hoped to increase Pannar’s confidence in our product and help them to avoid any testing difficulties.”

The biology of seed-quality

Physiologically speaking, seed-quality is indicated by two attributes:

1. Standard germination – the ability of a seed to produce a normal seedling under favourable conditions. This is measured through standardised tests prescribed by ISTA and AOSA for the different crops. Standard germination tests include planting seeds in rolled towels, pleated paper of organic growth media.

2. Vigour – the ability of a seed to produce a normal seedling under stressful conditions. Most vigour tests are not standardised, although ISTA and AOSA provide certain proposals. Examples of vigour tests include accelerated ageing, rolled-towel cold test, tray cold test and saturated cold test. Additional evaluations can include germination rate, emergence rate, dry mass accumulation and shoot or root length.

Seed companies measure both these attributes to determine the quality of seed-lots before any treatment is applied to the seeds. The tests are repeated post-treatment to find out whether seeds perform differently in response to the chemicals or not.

READ THE LABEL FOR FULL DETAILS

- Celest® XL contains fludioxonil 25 g/l and mefenoxam 10 g/l (Reg. no. L6353, Act no. 36 of 1947).

- Cruiser® White contains thiamethoxam 600 g/l (Reg. no. L7546, Act no. 36 of 1947). CAUTION.

- Celest® XL & Cruiser® White are registered trademarks of a Syngenta Group Company.

- Syngenta South Africa (Pty) Limited, Private Bag X60, Halfway House, 1685.

- Tel. (011) 541 4000. www.syngenta.co.za Twitter: @SyngentaSA

- © Syngenta Ag, 2000. Copyright of these documents are reserved. All unauthorized reproduction is forbidden.