Application Technology Roadshow

As much as a third of a product can go to waste due to poor application practices. Fortunately, there is a lot growers can do to prevent their profits from running off leaves or being blown away by wind.

In January, Syngenta together with various institutions such as Citrus Research International, CropLife, Subtrop and SA Society for Plant Pathology (SASPP) hosted workshops about the real difference proper application can make to the efficacy of crop protection products. Crop focus was mainly on citrus, avocados, macadamia's, mangoes, small grains, row crops (maize, soybean and sunflower) and soft fruit.

These workshops were held in Letsitele, Nelspruit, Bloemfontein, Durban, Paarl en Moorreesburg and Syngenta reached more than 300 growers, agents and other important key stakeholders in the industry.

The main speaker at the workshops was Ron Wohlhauser, (Head: Syngenta Switzerland Application Technology). His main message was that application greatly influences the biological efficacy of a product. “Efficacy is not only determined by the intrinsic activity of the product; how the product is applied, the equipment setup and calibration, and the type of sprayer that is used all play a role,” Ron said. “Effective crop protection is only possible when the best product is applied in the best way. The product alone cannot do all the work.”

According to Ron various factors influence application efficacy, but the 80/20 principle applies: if the most important few are handled correctly, results will improve dramatically. At the workshop, he concentrated on four factors:

1. Application volume

Trees need not be covered 100% for the product to be effective, especially when it has a systemic mode of action. The trick is to find the balance between good coverage and run-off.

The lower the application volume, the more important are factors such as speed, pressure, nozzle choice and environmental conditions.

Volumes can be adjusted in three ways. The size of the nozzle can be changed for large adjustments, while tractor speed can be adapted for medium adjustments. When a small adjustment is needed, it is sufficient to alter pressure.

2. Maintenance and calibration of equipment

Not all equipment is suited to all products under all circumstances. Calibration should therefore be the first step. Although it is relatively complicated and time consuming, the benefits of improved efficacy and decreased losses due to drift and run-off make calibration worth the effort.

According to Ron, the minimum requirement is to calibrate sprayers before the spraying season starts. Depending on the number of hectares sprayed and the variability in tree size, another two or three calibrations might be necessary during the season.

Calibration elements include the speed at which the tractor moves forward, flow rate, pressure, air volume and speed, and the crop that will be sprayed. For instance, it is estimated that around 70% of growers worldwide use too much air during application.

Growers who feel uncertain about calibration, can consult resources such as the website of the European Crop Protection Association or approach Syngenta for assistance.

3. Nozzle selection and droplet size

Droplet size can be a tough nut to crack. If it is too big, the product runs off; too small and the product drifts away before reaching the target. Both cases result in poor coverage.

As much 25% of the product being applied can be lost due to drift. The nozzle that is used determines the percentage of fine droplets and therefore plays a significant role in the prevention of drift.

4. Coverage and distribution of droplets on the target

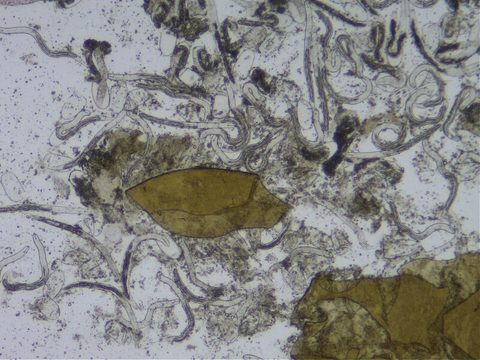

Coverage is expressed as number of droplets per cm2 of leaf and is mainly influenced by droplet size and spray volume. At a given spray volume, the bigger the droplets are the poorer the coverage; the inverse is true for smaller droplets.

When the spray volume is increased, the coverage will improve because the droplets become smaller.

Bigger droplets result in poorer coverage but they are not as susceptible to drift and penetrate the canopy more effectively. The opposite is again true for smaller droplets.

Given the disadvantages of bigger and smaller droplets, the rule of thumb is to always select medium-sized droplets – 0,2mm to 0,5mm.

Ron concluded his presentation by emphasising that it is possible to unlock the full biological efficacy of spray products. Growers have to apply the factors that were discussed within the context of maximum sensitivity towards environmental impacts and the health and safety of spray operators. “It is undoubtedly worth the effort to invest time and effort in application quality.”